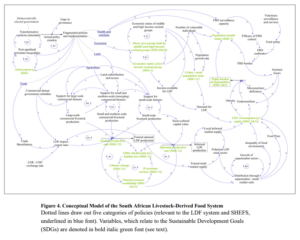

To give you an idea of the complexity of modern supply chains, and the evolution of supply chains over time, the image at the top of the post is a conceptual model of the supply chain for “just” the meat industry in South Africa11. Image credit: A systems analysis and conceptual system dynamics model of the livestock-derived food system in South Africa: A tool for policy guidance..

One industry, in one country.

When you extrapolate that to all the products we consume, and how manufacturing of components, subassemblies, and finished goods occurs all over the world, as well as the activities needed to coordinate this, you start to get a sense of the complexity of modern supply chains.

Table of Contents

Background/Perspective

This blog post is a summary, and perspective, of the first chapter of a paper published by the World Trade Organization (WTO) titled Supply Chain Perspectives.

This paper is “branded” as a WTO document to the point that the author or authors are not even identified.

I say “perspective” as while the paper I’m summarizing also talks about national income disparities in global supply chains, this post focuses only on the evolution of supply chains over time, and ignores national income disparities. Having said that, you can read the full paper via the link above.

To me, this paper is clearly “pushing” the WTO perspective. Per the WTO website, the WTO is…

In brief, the World Trade Organization (WTO) is the only international organization dealing with the global rules of trade. Its main function is to ensure that trade flows as smoothly, predictably and freely as possible.

As you read this, keep in the back of your mind that the WTO is not without critics.

Criticisms come from people of various political viewpoints.

From what looks like opposite sides of the political spectrum, we hear that:

- The WTO seems to clearly support multinational corporations over the residents of developing economies.

- The very negotiating of tarrifs is anthetical to free trade, as free trade requires the elimination of tarrifs.

So as you read this, bear in mind that while it does NOT read like a propaganda piece, it is presenting a viewpoint from the perspective of the World Trade Organization.

History

The roles of information technology in supply chains

Modern supply chains simply could not exist without relatively inexpensive computer systems and computer networking.

There seems to be a very direct link to the relative cheapness of global computing and telecommunications and the increasing complexity of our supply chains over time.

Without fiber-optic cables running along the bottom of the Pacific ocean, we might not today have smartphones at all, or at the very least, not nearly as cheaply as we do today.

The evolution of supply chains could not be at the level of today’s complexity without the IT revolution that started in the 1980s.

The movement of raw materials and finished goods

In the beginning, poor transportation technology meant that all over the world, communities produced most of what they consumed.

The advent of sailing ships, steamboats, steam-powered trains, and high-quality highways changed this.

We could now produce stuff in one place, ship it around the world, and consume it someplace else.

Pre-industrial revolution examples are sugar, tobacco, and cotton.

The movement of manufactured items started with the movement of finished goods during the industrial revolution.

For example, Colt revolvers were popular around the world, while being manufactured exclusively in the United States.

The same was true of porcelain products manufactured only in China.

In fact, porcelain products today are called “China” because they originally came only from China.

Verticle integration

Verticle integration is when a firm directly owns and manages the production of every component, and subassembly.

The textbook case of verticle integration was Ford in its early days.

Ford went so far as to own the forests where they grew the trees for the wood panels.

SIDE NOTE: This incidentally is where Kingsford Briquettes came from. They were initially made from the waste material from Ford’s wood panel factory.

Verticle integration still exists, but not so much with physical goods these days.

Netflix opening their own studio to produce their own content is an example of verticle integration, as it reduces their reliance on having to buy content from others.

The movement of sub-assemblies

As our manufacturing abilities got more sophisticated, regions and firms developed expertise in making certain things:

Regional specialization

- Northern Italy became the chocolate capital of the world (and invented Nutella) which was made by several firms.

Firm level specialization

- A French company (Valeo) became a major supplier of automobile air-conditioning systems to many European car manufacturers.

- BMW started making aircraft engines, which were sold to aircraft manufacturers.

In fact, if you’ve ever heard the phrase “OEM parts“, OEM stands for Original Equipment Manufacturer, and it specifically means sub-assemblies purchased from some other company.

Production fragmentation

Production fragmentation is a natural extension of firm-level specialization and is the extent of the evolution of supply chains today.

There is scarcely a product made today that is made by one company, let alone at one manufacturing facility.

Components and sub-assemblies are made by various firms around the world, shipped to the company who perform whatever the next steps are, and in the end, finished products are produced.

Do products really have countries of origin any more?

And this calls into question the way we identify the national origins of some products.

Clearly, onions that are grown in Mexico are from Mexico, but…

Are Toyota cars and trucks manufactured in Huntsville Alabama really Japanese cars?

Ford is now building cars in China. Are they American cars?

Services within supply chains

Geographic separation is now happening in services.

I visited a doctor in Round Rock Texas about 5 years ago and his medical scribe was in India.

He simply had an Internet-enabled audio link, via a speaker and microphone hanging on the wall, and rather than give directions to a medical scribe in the same room, he gave directions to a medical scribe on the other side of the world.

Call centers, data centers, other forms of transcription services, video editing, blog content creation, and pretty much any processing of information or content can now be done almost anywhere in the world.

Comparitive advantage and position within supply chains

The full spectrum of globalization and outsourcing activities are all based on the concept of Comparative Advantage, which essentially says activities and processes migrate to where some advantage allows it to be done cheaper.

While sometimes the comparative advantage is the possession of some needed resource (oil, lithium, etc), it’s also created by virtue of societal and cultural things.

The comparative advantage shows up in a countries exports, as, by definition, whatever a country is exporting is what other countries want from them.

Singapore has no natural resources to speak of but has managed to develop a comparative advantage in several sectors.

Singapore’s largest exports are machinery and transport equipment, electronics, chemicals and chemical products, miscellaneous manufactured articles, and electronic products.

Ireland has few natural resources to speak of but has managed to develop a comparative advantage in other sectors.

Ireland’s largest exports are pharmaceutical products, organic chemicals, optical (photo and medical) apparatus, electrical and electronic equipment, machinery (nuclear reactors and boilers), essential oils (perfumes, cosmetics, toiletries), and meat.

How do countries with few natural resources develop comparative advantages?

I’m afraid that as interesting a question as that is, it’s beyond the limited scope of this blog post.

I will dust off and examine that idea in a later post.

Footnotes

- 1